Shenzhen Mim Technology Co., Ltd

Shenzhen Mim Technology Co., Ltd

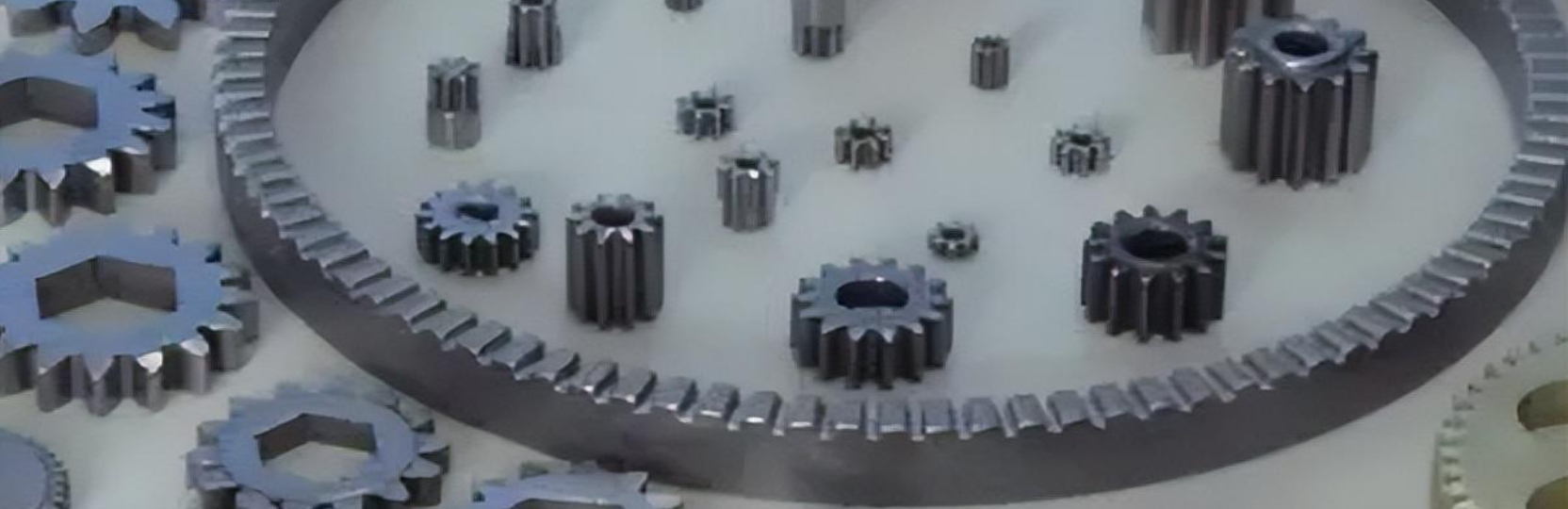

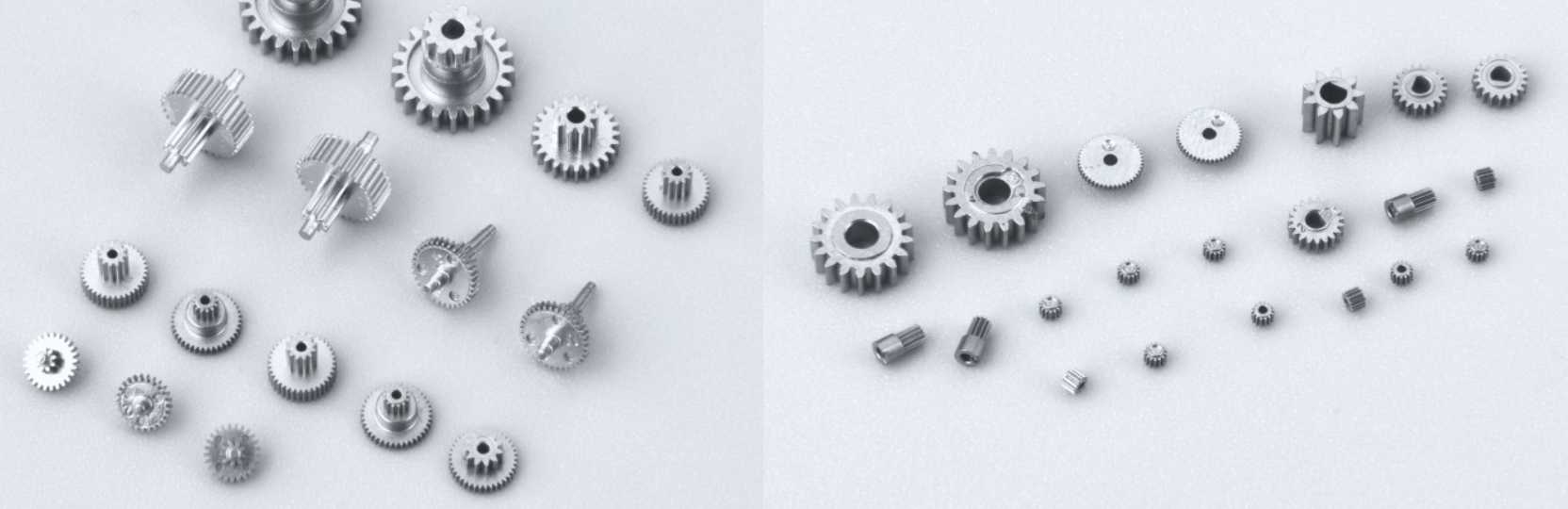

Powder metallurgy: the invisible champion of precision manufacturing, unlocking a new paradigm of efficient production. In the high-end manufacturing fields of automobiles, electronics, aerospace, etc., a precision processing technology of "zero into whole" is quietly becoming the core support - this is powder metallurgy. It uses metal powder as raw material, through a series of precisely controlled processes...

Learn more

Nowadays, consumers' demand for mobile phones has changed from "usable" to "easy to use", and light and thin body, integrated design and multi-functional integration have become the mainstream trend. With the characteristics of lightweight, near-net forming and multi-material composite, powder metallurgy technology perfectly adapts to the development needs of lightness and integration of mobile phones. In hand...

Learn more

At a time when mobile phones are developing towards high performance, long battery life and lightness, the performance of core components directly determines the user experience. With the advantages of precision molding, controllable performance and efficient utilization of materials, powder metallurgy technology has achieved breakthroughs in the core links of mobile phone heat dissipation parts, structural brackets, connectors, etc., and upgraded the performance of mobile phones...

Learn more

The requirements for parts in the medical field are not only stable performance, but also emphasize biocompatibility, safety and customization - not only to adapt to the human physiological environment, but also to meet the personalized needs of different patients. With its precise performance regulation and flexible molding ability, powder metallurgy technology can be used in medical implants, precision medical...

Learn more

The performance requirements for parts in the aerospace field can be called "strict" - they need to work stably for a long time in harsh environments such as high temperature, high pressure, strong radiation, extreme temperature difference, etc., and the control of weight and accuracy is extremely strict. With its unique advantages in high-performance material molding and complex structure manufacturing, powder metallurgy technology has become...

Learn more

In the process of transforming the automobile industry to lightweight, energy-saving and intelligent, powder metallurgy technology has become a key support for the manufacture of core parts of automobiles with its advantages of precision molding and efficient utilization of materials. From the engine system of traditional fuel vehicles, to the motors and battery components of new energy vehicles, powder metallurgy products...

Learn more

Against the background of the "dual carbon" goal becoming a global consensus, the green transformation of the manufacturing industry is imminent. With the advantages of low energy consumption, low pollution and resource recycling, powder metallurgy technology has become an important force in promoting the low-carbon development of the industry. Its green characteristics are highly in line with the environmental protection needs of modern manufacturing. Low energy consumption is powder...

Learn more

Different industries have very different needs for the performance of parts: automobile engine parts need to be high-temperature and wear-resistant; aerospace parts need to be high-strength and fatigue-resistant; medical implants need biocompatibility and bone fusion...... With its excellent performance customization ability, powder metallurgy technology can accurately adjust according to the needs of different scenarios...

Learn more

At a time when the profit margin of the manufacturing industry is squeezed by fluctuations in raw material prices and rising labor costs, powder metallurgy technology has become the "life-saving straw" of many enterprises with the dual advantages of "cost reduction + efficiency increase". Its performance in cost control and production efficiency improvement far exceeds that of traditional processing technology, injecting into the development of the industry...

Learn more

The Ministry of Industry and Information Technology issued the "Guiding Opinions on the Development of Powder Metallurgy Industry" to clarify the target of high-end localization rate in 2027.

Learn more

Along withThe requirements for range of new energy vehicles are constantly improving, and lightweighting has become a key area for the competition of automobile enterprises. Powder metallurgy technology has ushered in an application explosion with the advantages of materials. The reporter learned from the new energy vehicle parts exhibition held recently that at present, among the models of mainstream new energy vehicle enterprises, the amount of powder metallurgy parts has been from...

Learn more

The International Market Research Institute recently released the 2025 Global Powder Metallurgy Market Development Report. According to the data, the global powder metallurgy market will reach 8.861 billion US dollars in 2024, which is expected to exceed 9.5 billion US dollars in 2025, and is expected to climb to 150 billion in 2031. .100 million US dollars, with a compound annual growth rate of 7.6%. Its...

Learn more

Recently, a new materials technology enterprise in Jiangsu announced that the first powder metallurgy high-end aviation components production line with independent intellectual property rights in China was officially put into production. The production line adopts the integrated process of "high-temperature alloy powder + hot isostatic sintering", which can produce 50 key components such as aircraft engine turbine discs and combustion chambers...

Learn more

Powder metallurgy technology: the pattern at home and abroad is differentiated, and the market demand is multi-point explosion

Learn more

Significant advantages: multiple characteristics meet the needs of modern manufacturing. "The biggest advantage of powder metallurgy molding technology is that it can reduce costs and increase efficiency while ensuring the high quality of parts." Engineer Wang, the technical director of an auto parts manufacturing enterprise, said in an interview. According to its introduction, the core advantages of this technology are first of all reflected in...

Learn moreDedicated to MIM micro module gears, micro gearbox motors, and 3C components Production reaches 2.7 million MIM gears delivered daily