Shenzhen Mim Technology Co., Ltd

Shenzhen Mim Technology Co., Ltd

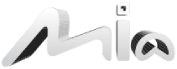

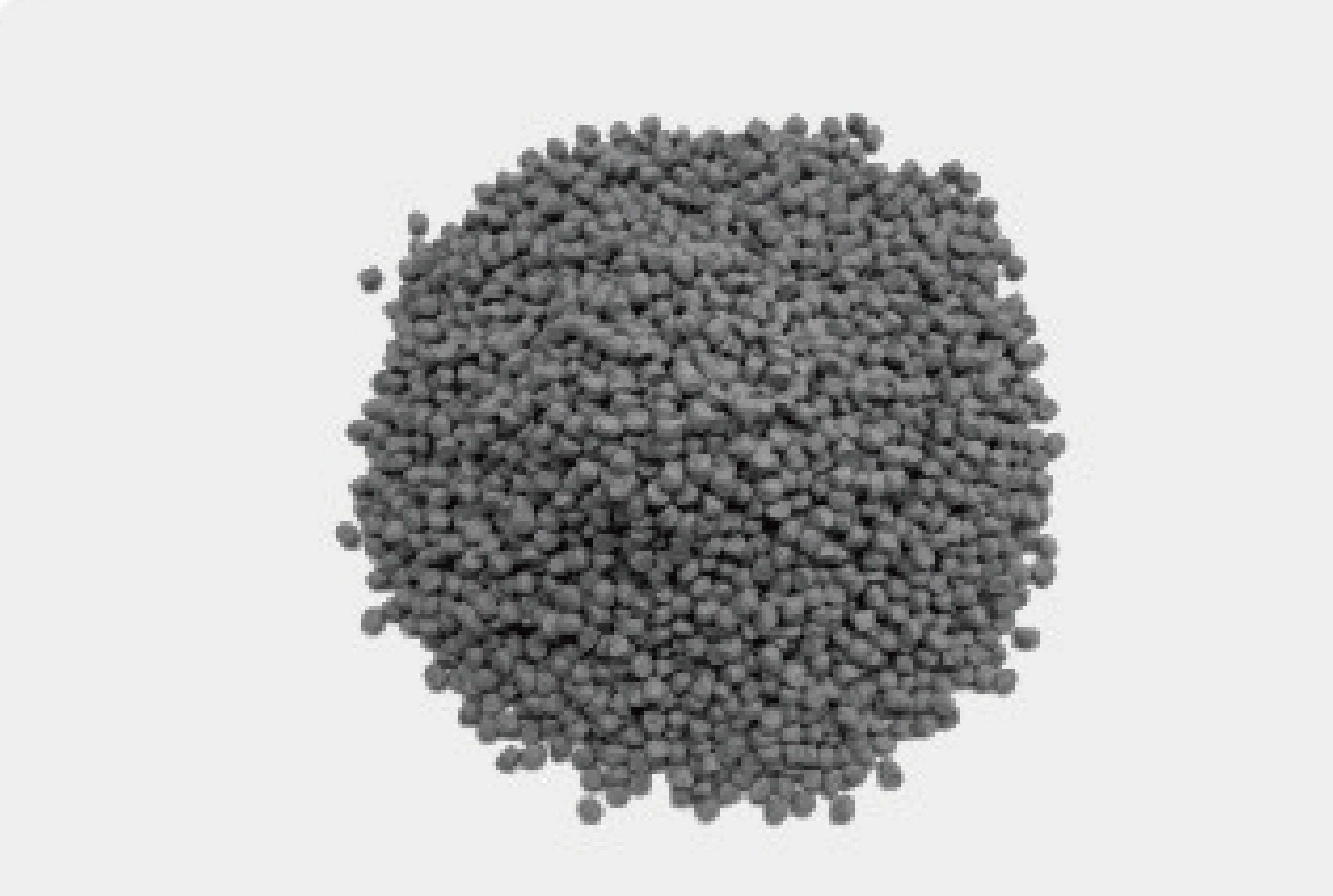

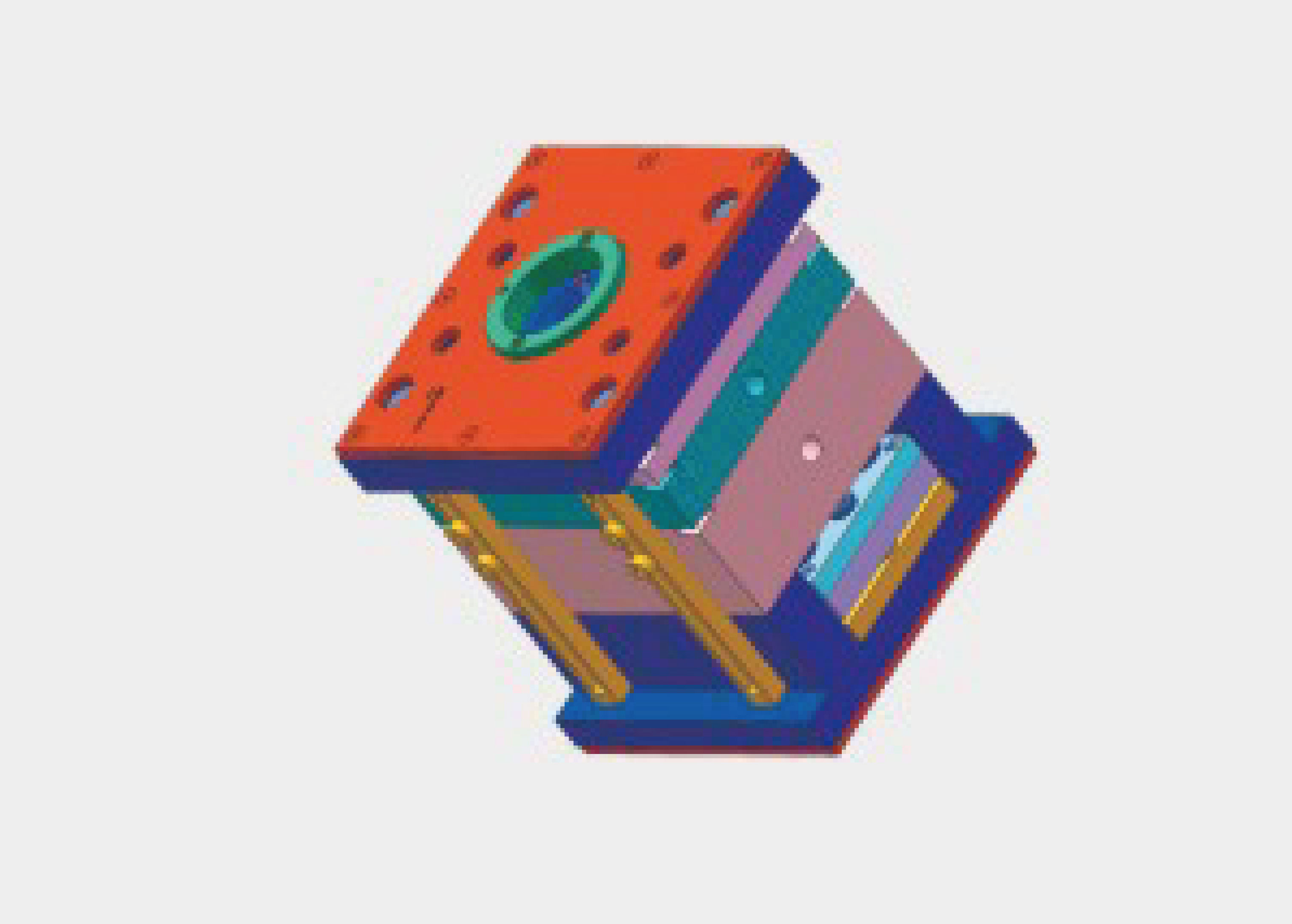

Just like plastic products, small metal parts with complex shapes are produced, usually weighing 0.1~200g.

☆ Good surface finish, high dimensional accuracy, the usual tolerance is 0.3%~0.5%.

The material has a wide range of applications, high density (up to 95%~99%), uniform structure and excellent performance

The product quality is stable, the production efficiency is high, and it can realize automation, mass and large-scale production.

Thin-walled structure is allowed, and the minimum wall thickness can be 0.3mm.

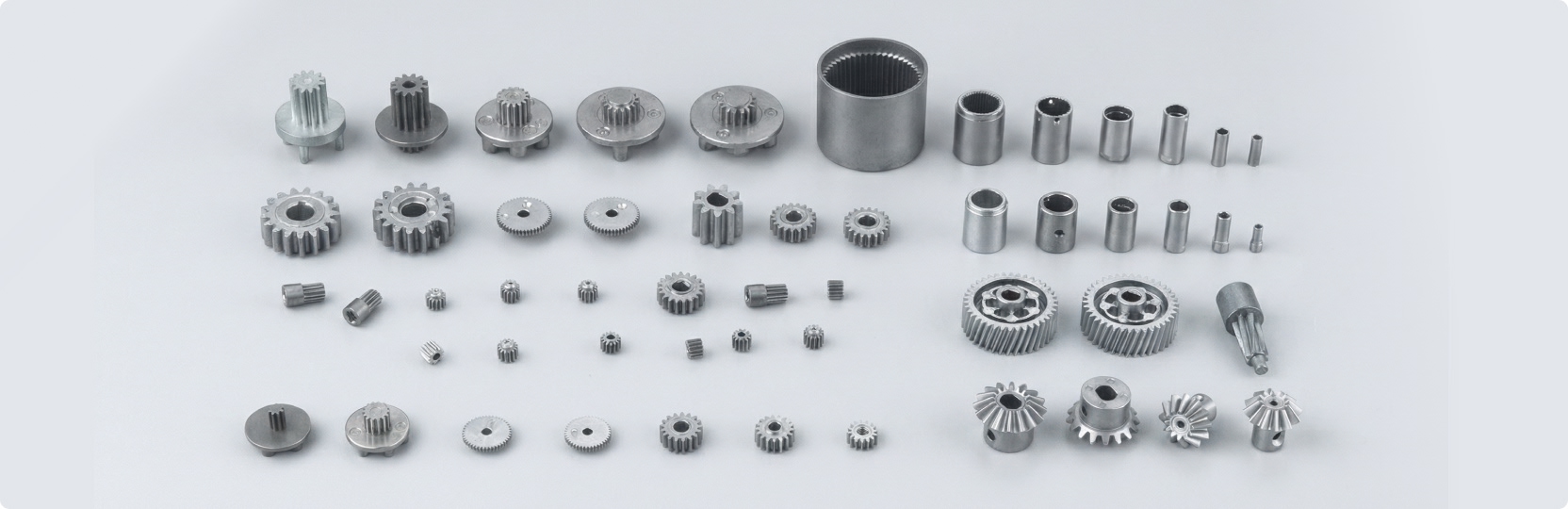

Dedicated to MIM micro module gears, micro gearbox motors, and 3C components Production reaches 2.7 million MIM gears delivered daily